The SWF500-SS by Shindaiwa is a wire feeder device developed by the Japanese conglomerate Yamabiko, compatible with most diesel welders and welding machines. The mechanism allows welding with wire diameters ranging from 0.9 to 2.4 mm. The Duty Cycle is 100% at 340A and 60% at 500A. With the SWF500-SS, operators can perform welding with aluminum, stainless steel wires, including solid and flux-cored welding wires.

A notable advantage of the SWF500-SS Shindaiwa mechanism is that welders can work seamlessly with both solid and self-shielding wires without changing the torch.

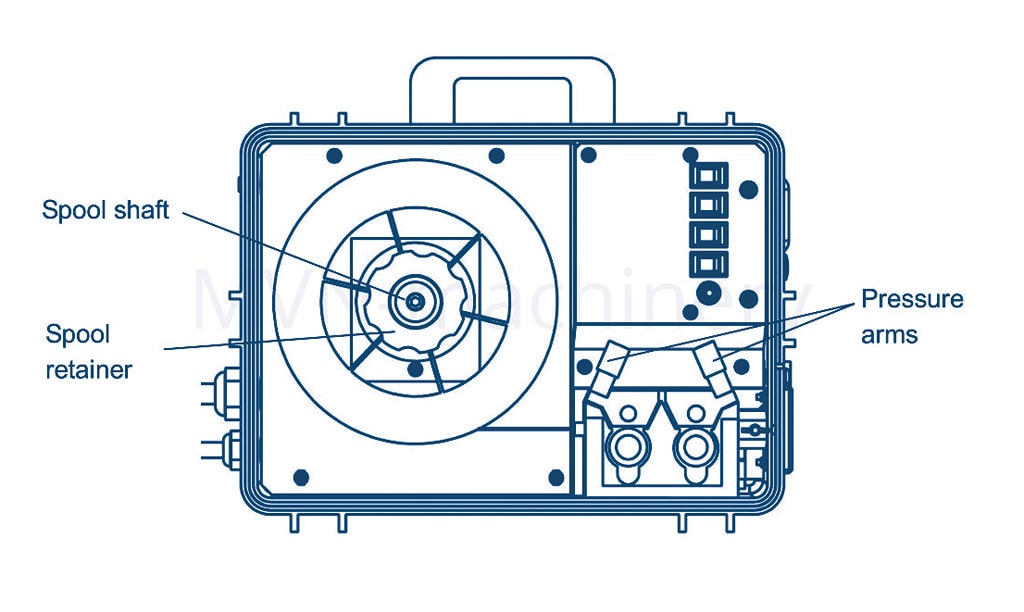

The mechanical part of the wire feeder device is based on the 4GearDrive feeding system by Yamabiko. The four main rollers of the SWF500-SS mechanism are resistant to clogging and ensure a consistent feed of welding wire without slipping.

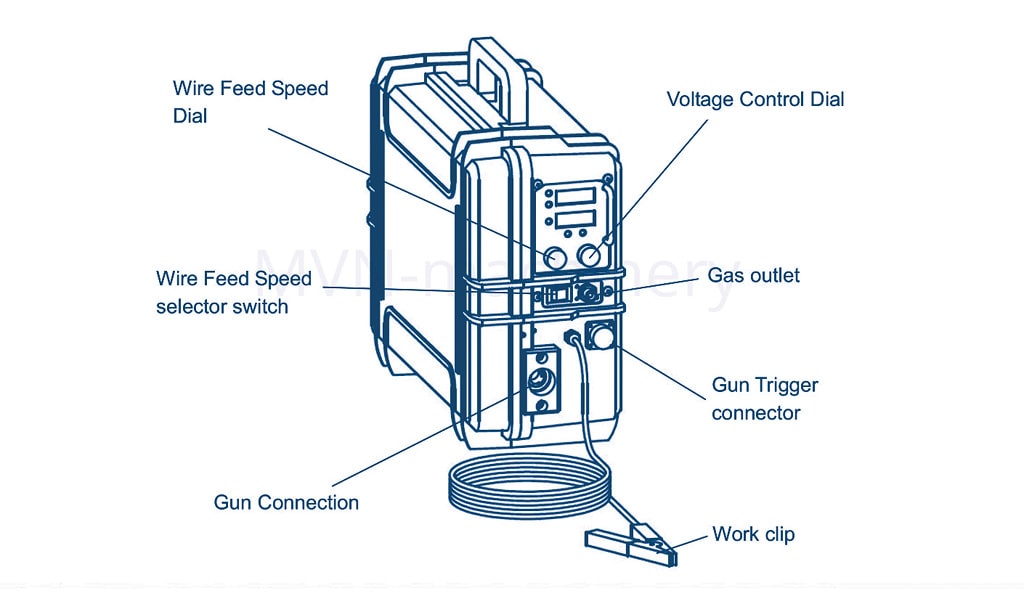

The front panel of the SWF500-SS Shindaiwa is equipped with:

- Digital indicators;

- Adjustment knobs for voltage and current;

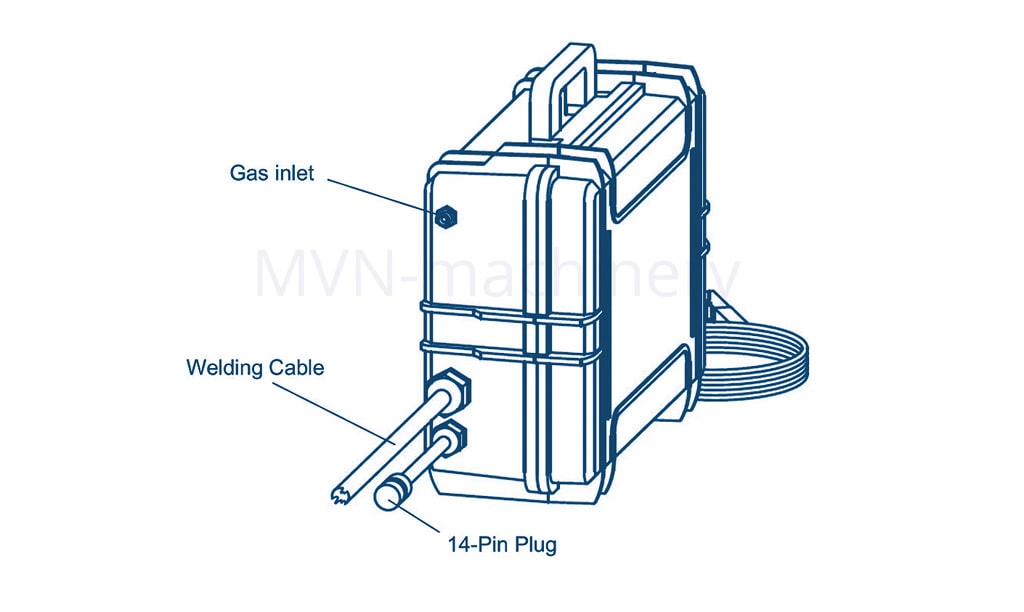

- A 14-pin connector for connecting to a Diesel Welder (e.g., DGW400) or machine for remote control.

The Shindaiwa wire feeder is lightweight and compact (weighing 16 kg, length 555 mm) and has the appearance of a standard case. The SWF500-SS can be easily carried by hand and transported in the trunk of a car.

Key Advantages of Wire Feeder SWF500-SS Shindaiwa

- Reliable mechanics with the 4GearDrive feeding system;

- Use of a single torch for different types of wire;

- Lightweight and compact design (dry weight of 16 kg);

- Remote control capability (standard 14-pin connector);

- Significantly simplifies the welding process.