TWO SUPERIOR ARCS

TWO SUPERIOR ARCS IN ONE UNIT

DIESEL WELDER

DIESEL WELDER WITH 5 MODES

CONNECTING EXTRA TOOLS

CONNECTING EXTRA TOOLS TOTALING MORE THAN 10 KW

LONG WORKING TIME

LONG WORKING TIME ON ONE FILL-UP

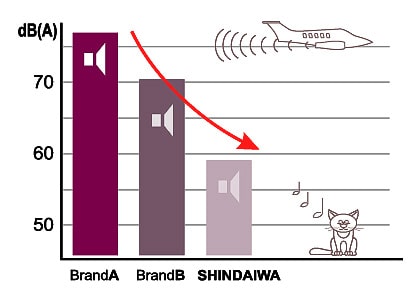

LOW NOISE LEVEL

LOW NOISE LEVEL ONLY 66 dB

See details about diesel Shindaiwa

SHINDAIWA DIESEL WELDER DGW400DMK

Shindaiwa welding machines are highly regarded for their exceptional performance and durability in the welding industry. Renowned for their advanced technology and precision engineering, Shindaiwa diesel welders are designed to meet the demanding needs of professional welders and fabrication shops.

These welding machines are meticulously crafted with attention to detail, ensuring that every component is of the highest quality. From their robust chassis to their powerful internal components, Shindaiwa diesel welders are built to withstand the rigors of heavy-duty welding tasks.

Shindaiwa welding machines offer a wide range of welding processes, including shielded metal arc welding (SMAW), gas metal arc welding (GMAW/MIG), flux-cored arc welding (FCAW), and tungsten inert gas welding (TIG). This versatility allows welders to tackle various welding applications, from light gauge sheet metal to heavy structural steel.

USING SHINDAIWA AS A GENERATORR

Shindaiwa welder equipped with Simul Phase™ technology for simultaneously 120-240V single-phases, 240V 3-phases & welding use.

3-Phase 240V

- The equipment includes one 3-phase 240V receptacle.

- The maximum output available from the receptacle is 15kVA.

1-Phase 120/240V

- The equipment includes one 1-phase 120/240V receptacle.

- The total maximum output available from the receptacle is 4.8/9.6kVA.

1-Phase 120V (GFCI)

- The equipment includes four (2set) 1-phase 120V receptacles.

- The total maximum output available from the four (2set) receptacles is 4.8kVA.

MVN-machinery - Supply and Service of Diesel welders and Generators in the USA

INFORMATIVE CONTROL PANEL

The control panel of Shindaiwa diesel welder machines is thoughtfully designed to provide welders with easy access to essential functions and settings. It offers a user-friendly interface that enables precise control and monitoring of the welding process. Here is a description of the typical features you might find on a Shindaiwa diesel welder control panel:

1. Engine Controls: The control panel features controls for starting, stopping, and regulating the diesel engine such as Hige Idle, Auto and ECO-mode including engine Pre-Heating;

2. Welding Process Selection: The control panel allows for each operator particularly to switch between different welding modes such as CV-WIRE, DROOP-STICK, GOUGING, "LIFT START TIG" or CC-STICK according to the type of welding being performed. The front panel of the diesel welder has separate buttons and controls for welding parameters for each operator;

3. Current or voltage adjustment knobs are available for each operator as well as arc hardness adjustment;

4. Digital displays: display the actual and preset welding parameters, as well as display the voltage of the electric generator 240V/3P and the frequency of the current. When failure, error or malfunction occurs, the diesel welder display shows the code of such a malfunction or problem, allowing the operator to quickly eliminate it;

5. Status indicators are always informing the welder about errors, remaining fuel, engine status, weld settings, etc. It is easy and convenient for the user. The diesel fuel indicator has a backlight so that it can be clearly seen at night;

6. Convenient buttons and knobs: The panel is made for easy operation even when wearing welding gloves. This facilitates interaction for the operator. All diesel welder controls are dust and splash proofed so no additional cover is required. The sockets for remotes and for the control cable of the wire feeder connecting are protected and safe;

The Shindaiwa DGW400 has a user-friendly and intuitive control panel, which positively affects the efficiency and speed of operation.

NOISE LEVEL

The control panel of Shindaiwa welding machines is thoughtfully designed to provide welders with easy access to essential functions and settings. It offers a user-friendlyinterface that enables precise control and monitoring of the welding process. Here is a description of the typical features you might find on a Shindaiwa control panel:

1. Power Switch: The power switch allows the operator to turn the machine on or off, ensuring convenient operation and energy efficiency.

SPECIFICATIONS DIESEL WELDER

Welding Generator

-

CC DROOPSingle field Dual field

-

Rated Current)380 200

-

Rated Voltage (V)35.2 28.0

-

Duty Cycle (%)60 100

-

Current Adj. Range (A)30 – 390 30 – 210

-

Welding Rod (in.)5/64 – 5/16 5/64 – 5/32

-

Gouging Rod (in.)1/8 – 5/16 1/8 –3/6

-

CVSingle field Dual field

-

Rated Current (A)340 200

-

Rated Voltage (V)32.0 21.0

-

Duty Cycle (%)100 100

-

Current Adj. Range (A)60 – 400 60 – 210

-

Voltage Adj. Range (V)14 – 35.0 14 – 28.5

-

Welding Wire (in.)025 - 5/64 025 - 1/16

-

Rated Speed (rpm)3600

-

No Load Voltage (V)MAX 85

AC Generator

-

Rated Frequency (Hz)60

-

Rated Speed (rpm)3600

-

RatingContinuous

-

Phase1 Phase 3 Phase<

-

Rated Voltage (V)120 120 / 240 240

-

Rated Current (A)20Ax2 40Ax1 36A×1

-

Rated Output (kVA)4.8 4.8 / 9.6 15.0

-

Power Factor1.0 0.8

Engine

-

Model (Manufacturer)D902 (Kubota)

-

TypeVertical,

Water-Cooled 4-Cycle Diesel Engine -

Displacement (cu.in. / liters)55 / 0.898

-

Rated Output (hp / rpm)23.6 / 3600

-

FuelASTM No.2-D,S15 EPA regulation

-

Fuel Tank Capacity (gal. / liters)11.4 / 43

-

Lubricant OilAPI Class CF

or better (CJ excluded) -

Lubrication Oil Volume (gal. / liters)0.95 / 3.6 (Effective 0.45 / 1.7)

-

Cooling Water Volume (gal. / liters)(Sub Tank Capacity)1.06 / 4.0 (0.16 / 0.6 included)

-

Starting Motor Capacity (V - kW)12 - 1.2

-

Charging Alternator Capacity (V - W)12 - 150

-

Battery Capacity (V - Ah)12 - 36 (46B24L)

-

Dimension(in. / mm)

-

Length56.5 / 1435

-

Width27.6 / 700

-

Height33.4 / 848

-

Weight(lbs. / kg)

-

Dry Weight1045 / 474

-

Net Weight1149 / 521